Climbing Devices by Winola Industrial

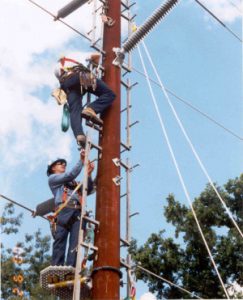

Winola Industrial Inc. are the original manufactures of climbing ladders and accessories that are the industry standard for utility structures around the world for decades. Our Ladders are ideal for use on steel poles, towers and any other application where “bucket” trucks and other conventional methods won’t work, or need to be supplemented. They provide both increased versatility and security, as they can be removed when your work is done, or can be left in place for perminent access.

Winola Industrial Inc. are the original manufactures of climbing ladders and accessories that are the industry standard for utility structures around the world for decades. Our Ladders are ideal for use on steel poles, towers and any other application where “bucket” trucks and other conventional methods won’t work, or need to be supplemented. They provide both increased versatility and security, as they can be removed when your work is done, or can be left in place for perminent access.

Features and Advantages

- Rugged, Load-Tested*, All- Steel Construction

- 100% Domestic Materials and Manufacturing

- Step Bolt Features:

- Large 3/4″ Diameter for Strength & Safety – beware inferior 5/8″ diameter steps.

- Meet or Exceed ASTM A394 Spec. for Tower Bolts

- Charpy Impact Tested & Knurled for Slip-Resistance

- Ladder frame provides a secure anchor point for lineman’s lanyards, and high-strength design even allows rigging directly from the ladder frame*

* Load Test Data Available Upon Request.

When you’re servicing overhead transmission poles in limited access areas, you cant always rely on “bucket” trucks alone. Our made-to-spec, load-tested* climbing devices get you up on the pole in places buckets simply cant reach:

When you’re servicing overhead transmission poles in limited access areas, you cant always rely on “bucket” trucks alone. Our made-to-spec, load-tested* climbing devices get you up on the pole in places buckets simply cant reach:

- Rough Terrain

- Dense Woods

- River Crossings

- Congested Urban Areas

- Restricted R-O-W

- Extra High Poles

Climbing Devices for any Job

Standard Climbing Ladder types -Steps are staggered for climbing.

CL-1: Galvanized Climbing Ladder Assembly, 3′ – 10 1/2″ Leg Spacing (“odd” spacing)

CL-2: Weathering Steel Climbing Ladder Assembly, 3′ – 10 1/2″ Leg Spacing (“odd” spacing)

CL-3: Galvanized Climbing Ladder Assembly, 2′ – 6″ Leg Spacing ( “even” spacing)

CL-4: Weathering Steel Climbing Ladder Assembly, 2′ – 6″ Leg Spacing (“even” spacing)

Standard Working Ladder Types -Steps are adjacent, proving more handfolds/footholds for working.

WL-1: Galvanized Working Ladder Assembly, 3′ – 10 1/52″ Leg Spacing (“odd” spacing)

WL-2: Weathering Steel Working Ladder Assembly, 3′ – 10 1/2″ Leg Spacing (“odd” spacing)

WL-3: Galvanized Working Ladder Assembly, 2′ – 6″ Leg Spacing (“even” spacing)

WL-4: Weathering Steel Working Ladder Assembly, 2′ – 6″ Leg Spacing (“even” spacing)

CL-1, CL-2, WL-1 and WL-2 are more common designs

Custom Ladders: We’ve built a large variety of custom climbing devices for our customers. We can fabricate brackets or attachments to adapt to your specific fall-prevention, fall-arrest, or other safety hardware. We can work with you to retrofit ladders to your existing structures or replace outdated climbing steps. All of our climbing devices are built with the same emphasis on quality, fast turn-around and top-notch service that goes into every ladder we make.

Accessories:

Ladder Clips– We mass produce ladder clips specifically designed for mounting our ladders to steel poles, towers, or any other structure, Avaliable in ASTM A36 (weld to structures to be galvanized), or in ASTM A588 (weathering steel).

Steps Bolts– We frequently carry a large inventory of step bolts, both weathering steel and galvanized. all are made in USA, custom knurled for slip resistance and charpy impact-tested with test reports available.

Winola Industrial Inc.

5790 Mislevy Rd

Factoryville, Pennsylvania 18419

Phone: 570 378 3808

Fax: 570 378 2597

www.winola-industries.com

Share on Socials!

The Light Bulb Scaffold™ System at LeTourneau University

HydraBed Reel Winder Option Now Available

Ironclad Performance Wear Has Launched the World’s First NFPA 2112 Flash Fire Certified Glove in Partnership With Dupont™

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!