Understanding Testing and Rating of PPE Rubber Insulating Gloves

By Richard A. Rivkin, Contributor

Tested, arc-rated, shock protection, class, AC, DC, ASTM, OSHA, and more – what do they all mean?

Live line working at distribution voltages up to 34.5 kV AC requires the finest quality protective equipment to keep the line worker safe. In the U.S., OSHA specifically mandates the use of rubber insulating products and related tools and equipment that has been manufactured and tested to specifications developed by ASTM International, a consensus standards organization. Many ASTM standards have also been approved as American National Standards and covered products are often marked with a dual ANSI/ASTM label.

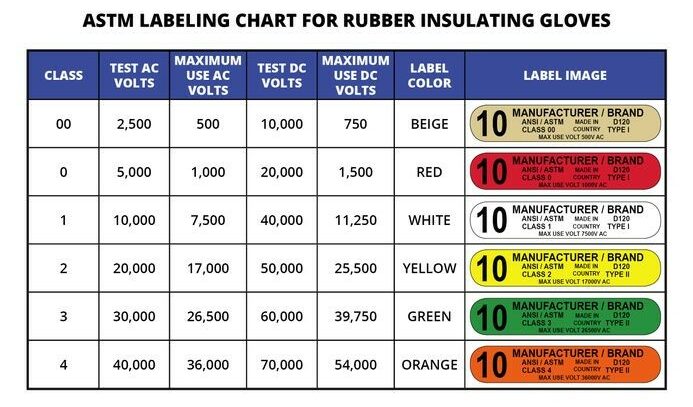

Users of rubber insulating gloves, for example, are accustomed to seeing a color-coded label indicating a voltage class (00 – 4) and a maximum usage voltage when working on AC equipment. The specifications driving that class and voltage data provide for a significant margin of safety. For example, gloves rated class 2 for working voltages up to 17,000 volts AC are 100% proof tested at 20,000 volts AC and samples of each production batch are tested to withstand at least 30,000 volts AC.

AC vs. DC Testing

AC vs. DC – A deep dive into the ASTM standards shows test voltages and maximum use voltages for both AC and DC. While there is no fixed formula relating the AC test and working voltage levels to DC test and working voltage levels, users can choose either. The reasons for having both AC and DC testing are complex. AC testing is both an electrical test and a physical test since the current is passing through the material back-and-forth 60 times per second. This also creates a corona-generating ozone, which is harmful to natural rubber. Among the benefits of AC testing is that manufacturers all test their products using AC and, most importantly, distribution voltages are AC so “test it as you use it” makes sense.

Some engineers postulate that DC testing of rubber insulating products is a purer test because the DC will find the weakest spot in the rubber exclusive of the physical effects of AC testing. In addition, DC testing does not create ozone, thus eliminating a source of potential damage to natural rubber products. Of increasing interest is the “test it as you use it” approach to wearing rubber insulating gloves (and other products) for protection against DC energized circuits and equipment found in EV (electric vehicles including hybrid), public transit systems, and renewable power generation.

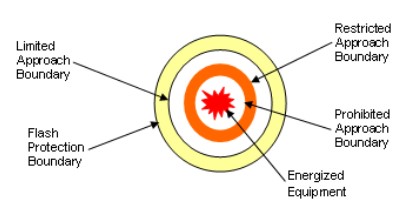

This graphic shows the different boundaries from energized equipment. All but the extreme outer boundary have a shock hazard and require rubber insulating gloves.

Arc Protection

But what about those arc-rated gloves? Back in 2013 ASTM approved a test method for determining arc ratings of gloves used for electrical arc flash protection. Anywhere from five to 10 arc explosions occur every day in the U.S., and as many as 10 workers are killed or injured per day according to some past research. Arc flash events are a clear and present danger. Exposure to their intense heat for 1/10 of a second can cause a 2nd-degree burn. Temperatures of 205⁰ F will cause a 3rd-degree burn, leading to complete skin loss in the exposed areas. A pressure wave blast from a high-amperage arc can travel several feet with a force of up to 1,000 lbs. That’s enough to toss a victim backwards, causing injury from falls and impact. It can also cause hearing loss. Most often when there is an arc flash hazard there is also a shock hazard.

About 75% of arc flash incidents occur when a worker is near the equipment. NFPA reports 2/3 of workers involved in arc flash incidents were injured when companies failed to conduct an arc flash analysis for selecting PPE. A separate study found 40% of electrical incidents involved 250 volts or less, so it isn’t only high voltage that causes injuries. NFPA 70E details areas of protective clothing sometimes neglected by electrical workers. Jackets and rainwear, worn over arc-rated clothing should also be arc-rated. Underwear comprised of meltable fibers such as polyester, nylon, and spandex should not be worn. Sleeves should be fastened at the wrists and shirts tucked into pants. The legs of pants and sleeves of shirts should come completely down to the ankle and wrist, forming total coverage when combined with voltage-rated gloves, protective footwear, safety glasses, hearing protection, and hardhats.

OSHA has required compliance with arc protection standards since 2015. Employers must calculate the incident heat energy of any potential electrical-arc hazard exposures to employees and implement programs and systems based on the risk assessment. NFPA 70E requires specific levels of PPE for various types and ratings of electrical equipment. OSHA estimates that 80% of electrically related accidents and fatalities involving “Qualified Persons” are caused by arc flash/ arc blast. NFPA 70E is updated every two years (2021 is the latest edition).

While the best way to prevent arc flash and electrical incidents from happening is to de-energize equipment before use, there are many instances where turning off the power is not an option (or it could cause an even greater hazard). As such, employers and facility owners must establish safe practices to protect their workers against arc flash and electrical hazards.

There are hundreds (or more) of products on the market today that have an arc flash rating of some number of calories per square centimeter (cal/cm²). These ratings include determination of ignition withstand levels as well as flame resistance, as well as not melting or dripping. This is certainly useful, life-saving information and, as such, nearly all rubber insulating gloves on the market today have been tested for arc flash, in addition to the inherent shock protection. ASTM recently adopted a new specification for rubber glove protectors that meet specific performance requirements, which include arc ratings as well as resistance to cut and puncture hazards.

In the real world, most arc flash hazards also involve exposure to energized equipment, so solely arc-rated gloves (i.e. leather or fabric or combinations) should only be used outside of the arc flash boundary, which is the minimum “safe” distance from exposed energized conductors or circuit parts that has the potential for an arc flash. Refer to the attached graphic showing the different boundaries from energized equipment. All but the extreme outer boundary have a shock hazard and require rubber insulating gloves.

And that’s the (hopefully not) shocking truth! ESW

Richard A. Rivkin is President and Chief Executive Officer of Saf-T-Gard International, Inc., a privately held family-owned and -operated global supplier of industrial safety products based in Northbrook, Illinois. Founded in 1936 as Latex Glove Company, Saf-T-Gard carries on the tradition that was started more than 80 years ago: bringing customers the products, training and service they need to keep employees safe in the workplace. Saf‑T‑Gard actively operates the Voltgard® Test Lab, one of the largest, independent, NAIL4PET-accredited test labs for rubber insulating products in the United States. To learn more, visit www.saftgard.com.

All images courtesy of Saf-T-Gard.

Share on Socials!

Electrical Gloves: Best Practices for Building an Electrical Safety Program

Best Practices for Electrical Safety Programs

Your First Aid Kit Is (Probably) Outdated!

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!