What Are Absence of Voltage Testers and How Are They Used?

A Q&A with Marty Kronz from Panduit about AVTs and how they boost safety.

The VeriSafe 2.0 Absence of Voltage Tester (AVT) is a permanently mounted tester that is used to verify a circuit is de-energized prior to opening an electrical enclosure. Once installed, a push of a button enables personnel who have been trained on the operation of the tester to verify the absence of voltage and see an active indication when the absence of voltage is confirmed.

Q: How are VeriSafe 2.0 AVTs different from other products?

Kronz: VeriSafe 2.0 AVT utilizes new technology and has an enhanced set of features making it compatible with even more applications. These AVTs have all the AVT safety and reliability features you know and love, in addition to:

- Network connectivity: monitor voltage levels in real time, record AVT test results, and view AVT status

- Flexible power options: power the AVT test with battery, 24 VDC, or PoE

- Expanded voltage and environmental ratings: including indoor and outdoor applications up to 1000 V, service entrance, hazardous locations

- Optimized configurations: three-phase, single-phase, and DC power systems

- Ability to initiate the test from multiple locations

Whether you choose 1.0 or 2.0, all VeriSafe AVTs provide:

- Increased safety and risk reduction with no exposure to electrical hazards during test

- Increased productivity with results in less than 10 seconds

- Simplified process for easier compliance. The AVTs meet the requirements for permanently mounted absence of voltage testers described in NFPA 70E and CSA Z462

Q: Where are the best applications, equipment, and places for VeriSafe 2.0 AVT to be used?

Kronz: VeriSafe 2.0 AVTs can be used in even more applications across your facility, from power distribution to automation and motor control. Whether you have an industrial site, commercial facility, utility, or data center, we’ve got you covered.

See VeriSafe Absence of Voltage Testers in the Industrial Floor

See VeriSafe Absence of Voltage Testers in the Data Center

AVTs are often deployed in applications where frequent testing for absence of voltage occurs (control panels, motor control centers, switches) or where testing might be considered high-risk (test equipment, power distribution units, switchgear, transformers).

Q: Why are VeriSafe AVTs better than portable test instruments for absence of voltage testing?

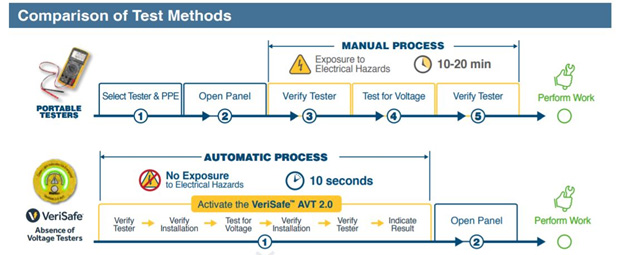

Kronz: When using a portable test instrument, you must verify the tester is working on a known voltage source, open the equipment and make sure the tester probes make good contact with each phase and ground while taking a series of measurements, then re-verify the tester on a known voltage source. This process is performed by a qualified electrical worker, can be rather lengthy and requires PPE to provide protection for exposure to electrical hazards.

VeriSafe AVTs allow a user to test for absence of voltage before doors and covers are removed. This reduces risk by preventing exposure to electrical hazards. Pushing the test button on the AVT triggers a test sequence that includes using a known voltage source to verify the AVT is working, confirming the AVT has good contact with the test point, and testing for absence of AC and DC voltage phase-to-phase and phase-to-ground. Results are displayed in less than 10 seconds! Permanently mounted absence of voltage testers like the VeriSafe 2.0 AVT are UL listed and recognized as an acceptable method for testing for absence of voltage in NFPA 70E and CSA Z462.

Q: Who can use VeriSafe 2.0 AVTs?

Kronz: VeriSafe 2.0 AVTs are designed for anyone who may need to test for the absence of voltage. From mechanical operators to production associates, technicians, electricians, and engineers alike, VeriSafe AVTs make testing for absence of voltage safe and efficient.

Q: Explain the automated process of testing electrical safety equipment and the benefits that come from it.

Kronz: VeriSafe Absence of Voltage Testers:

- Confirm power is available to perform the test

- Checks the health of key circuit elements

- Verifies threshold circuits in tolerance

- Checks on known voltage source

- Verifies connectivity

- Verifies threshold is under 3 Volts

The benefits to VeriSafe AVTs over traditional testing are:

- Built-in known voltage source

- Verifies the tester is contact with the test point

- Keeps hazardous voltage off the door

- Diagnostic codes provide intelligence

- Built-in overcurrent protection

- Automatically self-calibrates

- Recognized by standards and certifications like UL and NFPA 70E

Q: How much time can electricians, maintenance personnel, and operators save with VeriSafe 2.0 AVT? How does this simplify electrical testing?

Kronz: Using portable test instruments, a typical absence of voltage test may take 10-20 minutes. VeriSafe AVTs provide the same results in less than 10 seconds!

In addition, when the VeriSafe 2.0 AVT is used with the Network Module, you can monitor voltage levels in real time. This allows you to detect undervoltage (phase loss) or overvoltage (surge) conditions, while keeping doors and covers closed for troubleshooting.

Q: What powers the absence of voltage test?

Kronz: AVTs must have an independent power source to operate the test and ensure all of the reliability requirements are met when the test for absence of voltage occurs. VeriSafe 2.0 AVTs are designed with flexibility in mind, allowing you to configure the product to best suit your application. Options for powering the test include battery, auxiliary DC, or power over ethernet (PoE).

Q: How does VeriSafe 2.0 AVT help mitigate risks for facility and plant managers?

Kronz: Engineers at Panduit leveraged prevention through design principles to reimagine the absence of voltage testing process, looking for ways to remove risk, reduce exposure, and eliminate the most common failure modes and errors that occur when using portable test instruments. The VeriSafe 2.0 AVT is an innovative approach that protects your people, processes, and equipment enabling you to operate safer, smarter, and more efficiently.

Marty Kronz is Manager of Business Development for Panduit product line – Prevention through Design. (PtD). The vision for this new PtD business is to deliver solutions for control and power distribution applications that reduce electrical workplace hazards through design. In this role, he leads the PtD business team defining its strategy, identifying problems, and developing innovative electrical safety solutions (www.panduit.com).

Share on Socials!

Arc Flash Relays: A Critical Component of Your Mitigation Strategy

Meet the new Panduit Absence of Voltage Testers

NFPA 70E® Training: A Springboard To Greater Safety And Health Performance Excellence

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!