Understanding Arc Flash PPE

By Joe Schomaker, Contributor

Nearly all electrical professionals are familiar with the dangers of arc flash — the fiery explosions that can result from arcing faults in electrical equipment.

But did you know employers are required by law to provide exposed workers with the correct level of personal protective equipment (PPE) to safeguard against these potentially deadly events? And non-compliance with this requirement exposes employees to serious safety threats and may result in hefty penalties for employers?

Arc flash hazards are real, and the consequences of wearing insufficient PPE can be devastating. It is critical that facility managers fully understand how to safeguard their employees, infrastructure, and productivity. To provide an introductory guide, this article will explore the various aspects of arc flash PPE compliance, including:

- Applicable electrical safety laws, codes, and standards

- The four levels of arc flash PPE

- Determining what type of PPE is right for your task

Applicable electrical safety laws, codes, and standards

When it comes to protecting workers from the dangers of arc flash, the following laws, codes, and standards play a key role through continuous research, communications, and enforcement.

- The Occupational Safety and Health Administration (OSHA) is a large regulatory agency of the United States Department of Labor that ensures safe and healthful working conditions for workers by setting and enforcing standards and providing training, outreach, education, and compliance assistance.

- The National Fire Protection Association’s National Electric Code (NEC) NFPA 70 provides a regionally adoptable standard for the safe installation of electrical wiring and equipment.

- The NFPA 70E Standard for Electrical Safety in the Workplace is a practical standard that addresses electrical safety-related practices in the workplace.

- The Institute of Electrical and Electronics Engineers (IEEE) 1584 Guide for Performing Arc Flash Hazard Calculations presents methods for the calculation of arc flash incident energy and arc flash boundaries.

Although PPE protects a qualified worker in the event of an arc flash event, it is meant to be used only after recognizing the hazards and taking steps to minimize or eliminate them. The first step in hazard identification and mitigation is to have an arc flash study performed to accurately estimate potential incident energy.

There are two methods that can be used for the selection of arc flash PPE: incident energy analysis in accordance with NFPA 70E 130.5(G) or arc flash category method per NFPA 70E 130.7(C)(15). The incident energy analysis is aimed at calculating how much energy an arc flash could release at various points along the power system. Per NFPA 70E 130.5(G), the analysis must be reviewed and updated whenever changes occur in the electrical distribution system that could affect the results. Additionally, it must be reviewed for accuracy every five years.

Incident energy is defined as the amount of energy at a prescribed distance from the equipment generated during an electrical arc event. It is dependent on the magnitude of current flowing in the fault and the clearing time of the fault. Accuracy is essential with such measurements, so managers who lack direct and extensive experience with arc flash incident energy analysis should always seek assistance from a qualified power systems engineer.

Upon completion of an arc flash incident energy analysis, companies should place warning labels on all pieces of electrical equipment that pose an arc flash risk. They should also place barriers and signs to prevent or limit access to work areas containing energized circuits and alert workers about electrical hazards that might endanger them.

Determining what type of PPE is right for your task

Technicians should never come within the arc flash protection boundary without wearing appropriate PPE such as arc-rated clothing, eye protection, and gloves. These protective layers are available in varying degrees of thermal protection.

If the incident energy analysis method is used, the PPE is selected in accordance with Table 130.5(G), which covers incident energy levels equal 1.2cal/cm2 up to and including 12 cal/cm2 and incident energy exposures greater than 12 cal/cm2. The worker must select all PPE listed in the table and it must have a rating equal to or greater than the calculated incident energy.

If the category method is used, the appropriate PPE category must be determined using Table 130.7(C)(15)(a) or 130.7(C)(15)(b) based on the equipment type or voltage rating. It is important to note that maximum available fault current and fault clearing time must be within the parameters listed in the tables; if they are not met, an incident energy analysis is required. Once the appropriate category has been determined from tables, the arc flash PPE is selected in accordance with the requirements called out in that category.

Table 130.7(C)(15)(c) ranks PPE by four category (CAT) levels. Each of these levels comes with specific arc flash safety requirements.

- CAT 1 requires PPE with a minimum arc rating of 4 cal/cm²

- CAT 2 requires PPE with a minimum arc rating of 8 cal/cm²

- CAT 3 requires PPE with a minimum arc rating of 25 cal/cm²

- CAT 4 requires PPE with a minimum arc rating of 40 cal/cm²

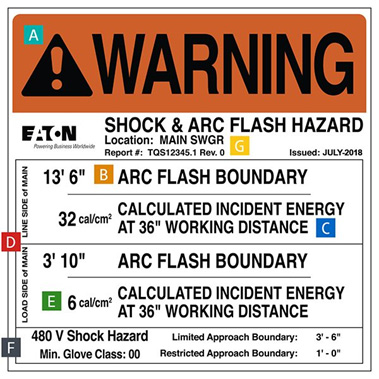

Arc flash warning labels

Equipment labels can warn employees of an arc flash hazard and the proper arc flash PPE required. Per NFPA 70E, section 130.5(H), electrical equipment such as switchboards, panelboards, industrial control panels, and motor control centers that are likely to require access while energized need to be marked with an arc flash warning label that must show the nominal system voltage, the arc flash boundary and information to select the proper PPE. This must include at least one of the following: (1) the available incident energy and corresponding working distance or the arc flash PPE category, (2) minimum arc rating of clothing, or (3) site-specific level of PPE.

It is important to understand that voltage alone does not determine the arc flash hazard. Knowing the voltage is only one piece of determining the required arc flash PPE. Many factors, including electrode orientation, available fault current (amps), the working distance between the worker and the equipment, the clearing time of the circuit protection device, the spacing between conductors or from a conductor to ground, the number of phases, whether the conductors are in an enclosure, and the equipment configuration, must all be considered when determining the potential severity of an arc flash hazard.

Example Arc flash warning label

-

The owner of the electrical equipment is responsible for providing shock and arc flash warning labels, which are required on electrical equipment over 50V that could be accessed while energized.

-

An arc flash boundary is the distance at which the incident energy equals 1.2 cal/cm2, and arc-rated PPE is required for any employee within the arc flash boundary.

-

The working distance is the distance from a person’s face and chest to the prospective arc source. Typical working distances, primarily based on equipment type, are published in IEEE standard 1584 and used in studies to perform the incident energy calculations.

-

While performing two sets of calculations for the loadside and lineside of the main on specific equipment is not specified in NFPA 70E, Eaton has made this a standard practice to enhance productivity and safety for equipment that has adequate isolation of the main protective device.

-

Calculated incident energy is the amount of thermal energy (cal/cm2) at a distance from an electrical arc event and indicates the level of PPE required to protect workers from third-degree burns.

-

Nominal voltage, limited, and restricted approach boundaries and PPE glove class are also displayed on the label to help protect workers from electric shock.

-

Eaton’s labels display the arc flash study report number for easy reference and label updates.

Incident energy analysis vs. arc flash PPE category

NFPA 70E states two methods can be used in an arc flash risk assessment to determine appropriate arc flash PPE. One is the incident energy analysis method using IEEE standard 1584-2018 calculations, which results in an incident energy value expressed as cal/cm2 at a typical working distance. The second is the arc flash PPE category method, which results in appropriate arc flash PPE selected directly from the NFPA 70E tables.

Using the example above, it appears that the NFPA 70E arc flash PPE category method is a simple lookup. However, to use these tables correctly, additional information such as available fault current, opening time of the overcurrent protective devices, and the working distance is required. First, the available fault current must be known or calculated. Second, the fault clearing time must be known. Table 130.7(C)(15)(a) has an informational note that gives “typical” fault clearing times for different types of overcurrent protection devices. (Actual fault clearing times may differ.) If the available fault current for this example is greater than 25 kA OR the fault clearing time is greater than 0.03 seconds, the arc flash PPE category method cannot be used, and an incident energy analysis must completed.

For accuracy, it is important that those who conduct either of these assessments have been properly trained and fully understand the requirements. It is also necessary to have access to a complete, up-to-date copy of NFPA 70E to properly apply the requirements.

Properly protecting personnel is critical

Arc flash events can do significant harm, ranging from disabling or fatal injuries to heavy fines and lawsuits. Fortunately, a wide range of proven technologies and techniques — and thoroughly documented laws, codes, and standards — are available to help organizations reduce or mitigate arc flash incidents and limit arch flash exposure to personnel.

The bottom line is that worker safety should always be the top priority, and if you haven’t taken the proper steps to determine what type of PPE is required to protect your workers, you’re jeopardizing what matters most.

Stay tuned for the second article in this series, in which we’ll explore what to look for when evaluating the many different PPE options across the marketplace.

Joe Schomaker is a manager of technical sales and marketing at Eaton where he leads a team of application engineers focused on helping customers properly apply overcurrent protective devices (www.eaton.com).

Share on Socials!

Understanding the Cybersecurity Standards Enabling Trusted IIoT Connections

Electrical Shock: Downplayed and Deadly

As the World Gets Hotter, There is a Push to “Electrify Everything”

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!