Lockout/Tagout Compliance: Implementing a World-Class Management System

By: Ricky Rodriguez, Contributor

Implementing a Lockout/Tagout (LOTO) is often mistaken as just developing procedures and training. This article will help explain what encompasses an effective Lockout/Tagout management system and best practices.

Lockout/Tagout compliance prevents 120 fatalities and 50,000 injuries a year, with injuries that can vary from amputations to electrocution. LOTO applies to both affected employees and authorized employees. The OSHA regulation reference for lockout-tagout is 29 CFR 1910.147.

The two most significant root causes of cases I have investigated throughout my years of experience are lack of training and complacency. When drilling into the root causes of accidents involving LOTO, the leading causes of accidents are:

- Lack of machine-specific procedures

- Failure to identify machine energy sources correctly

- No training for new hires

- No training for affected employees (only authorized)

- No lockout/tagout safety orientation for contractors and visitors

- Lack of communication between affected and authorized employees

- Failure to stop equipment

- Failure to apply locks and tags

- Lack of compliance enforcement (supervision)

When it comes to implementing a Lockout/Tagout system, writing procedures and training employees are only part of the program. A LOTO management system consists of various elements:

- Written lockout/tagout policy (describes what your machine lockout program requires)

- Inventory of equipment that requires lockout/tagout

- Inventory of padlocks and isolation devices

- Machine-specific procedures available for all work shifts

- Training (affected and authorized employees)

- Safety orientation for contractors and visitors

- Annual procedure audits

- Annual “authorized employee” procedure performance audits

- Procedure for abandoned lockout removal

- Periodic lockout program assessment

Lockout/Tagout applies to machines with multiple energy sources or when the energy source is not under the employee’s immediate control. Employers must provide training to authorized and affected employees.

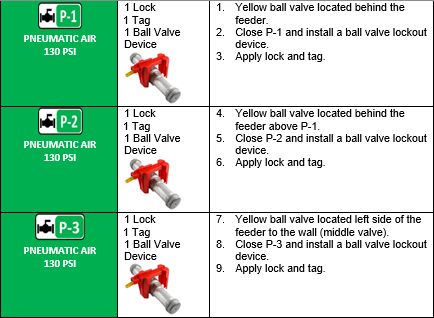

Written procedures must be machine or equipment specific to guide employees through the proper steps for isolating energy sources. Writing machine-specific lockout procedures requires knowledge of the machine energy sources and means for isolation. Identifying energy sources correctly in the lockout procedure is very important. Examples of energy sources and isolation methods are:

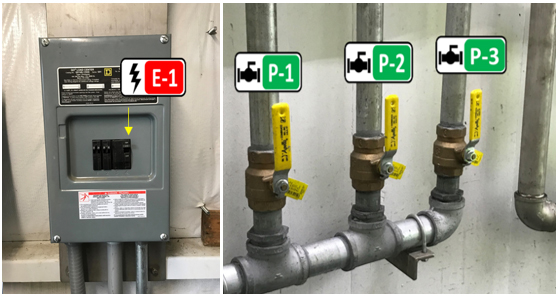

- Electrical: Physical Interruption (e.g., breakers, switches)

- Hydraulic/Pneumatic: Physical Isolation (e.g., Ball Valves)

- Chemicals: Physical Isolation (e.g., Ball or Gate Valves)

- Dangerous Gases: Removal or line disconnect with end caps or blind flanges.

- Heat: Time to cool down to a safe temperature

- Kinetic: Time to come to a complete stop

- Gravity: Install jacks, safety bars, etc.

Labeling machines clearly in the lockout procedure is essential to guide the employee through the isolation steps. Applying these labels to the energy point is an excellent way to help the employee find the isolation points.

When writing machine-specific lockout procedures, avoid using generic steps. A straightforward lockout procedure identifies every isolation point and details what isolation device to use and how to apply it. Lockout devices (e.g., ball valve, switch, or breakers lockout devices, etc) can be confusing. I often see devices installed incorrectly, and it all comes down to a lack of training.

The order of lockout steps may impact the machine-specific lockout procedure. These steps must be clear to avoid human error or confusion. Consider writing detailed steps for bringing the machine back to normal operations.

Machine-specific lockout procedures need to be available to employees for all working shifts. Lockout procedures can be either affixed to the machine or in a binder near the equipment operations.

Testing for machine isolation is one of the most crucial steps in the LOTO process after the machine is locked out. Employers must train employees to test the devices for energy isolation before performing work. Testing is how employees can verify that:

- The lockout procedure is the correct one

- Isolation points are labeled correctly

- Machine isolation points have not changed

- No damage to the isolation points or lockout devices

Machine testing techniques will depend on the machine’s capabilities. The most efficient method to ensure the device is safe for maintenance is testing for the absence of voltage with a calibrated meter. However, arc flash hazards need to consider in this case. Therefore, training/qualifying employees in arc flash hazards and proper arc flash PPE is crucial when testing machines for zero voltage. Machine lockout procedures should identify test points and provide clear instructions on testing machine operation.

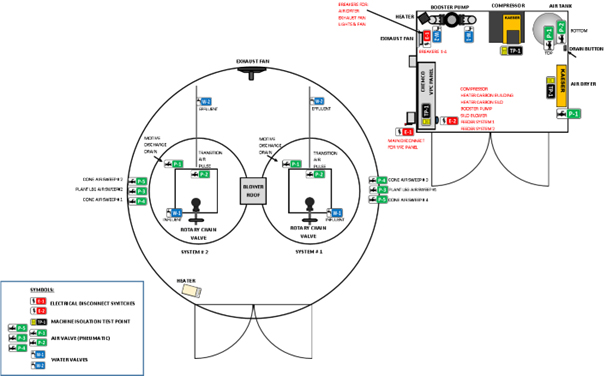

Machine signage, labeling of energy sources, and lockout/tagout maps are best practices that improve the machine lockout performance. Labeling machine isolation points is also a best practice to improve the identification of energy sources and testing points.

Mapping machine isolation points is another good practice for implementing a world-class LOTO program. Maps significantly reduce confusion and human error by identifying energy sources for isolating machines. It is also an excellent tool for training employees on the production line and providing safety orientation for contractors working in the facility.

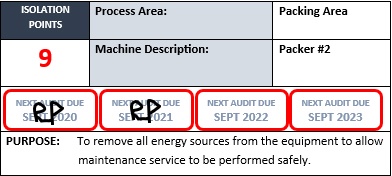

A sustainable lockout/tagout program requires audits by employees knowledgeable about the operations. There are three types of audits for the implementation of a compliant lockout management system:

- Lockout/tagout program audit

- Machine specific procedure audit

- Authorized Employee audit

Audits are required at least annually to certify that written procedures are accurate. It is essential to document the revision by updating revision dates or placing initials physically on the “Next Audit Due,” as illustrated below in a section of a lockout procedure.

Minor servicing is one exception to the lockout tagout process. However, you need to consider alternative measures to ensure a safe method. A minor servicing operation is the need to pause production for services such as cleaning, adjusting, or maintenance activities that are considered routine, repetitive, and integral to normal operations.

Minor servicing can also include unjamming tasks. However, it is crucial to ensure that energy cannot release during the unjamming process (e.g., overhead, gravity, spring-loaded, etc.)

Examples of alternative measures employees can implement for minor servicing are:

- Keyed control switches

- Interlocked barrier guards

- Local disconnects

- Remote devices

Using E-Stop buttons or any device intended for machine guarding is not acceptable for machine interruption during minor servicing operations (e.g., blocking light curtains, E-stop buttons, etc.). These devices are not effective methods for isolating machine energy.

Implementing a world-class lockout/tagout program can be an easy process when you understand the elements involved. Proper training, developing procedures, annual program audits, and good signage are vital elements for preventing accidents and improving compliance. ESW

Ricky Rodriguez is with Electrical Safety Specialists, LLC, Louisburg, KS. For more information about Lockout/Tagout and management system implementation, please contact Ricky Rodriguez (816) 925-0443, ricky_rod_asn@hotmail.com).

Share on Socials!

Why GFCIs, Prevention through Design, Need Greater Prioritization

How to Prevent and Respond to Arc Flash Injuries

The Ins and Outs of an Infrared Inspection Service

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!