Ensuring Worker Safety and a Safe Electrical System Through the Proper Grounding of Electrical Equipment

By Dean Austin, Contributor

Grounding, grounded, bonding, and bonded are all terms an electrician, electrical engineer, or facility manager is familiar with and use frequently, but what does it mean to properly ground electrical equipment? The initial thought is, it’s just connecting the branch circuit equipment grounding conductor to the electrical equipment grounding terminal. In simple terms that is correct, but it is more than that. First, we must understand what grounding is so the electrical equipment can have proper grounding.

Grounding, grounded, bonding, and bonded are all terms an electrician, electrical engineer, or facility manager is familiar with and use frequently, but what does it mean to properly ground electrical equipment? The initial thought is, it’s just connecting the branch circuit equipment grounding conductor to the electrical equipment grounding terminal. In simple terms that is correct, but it is more than that. First, we must understand what grounding is so the electrical equipment can have proper grounding.

For grounded systems, the grounding of electrical equipment is referred to in the 2020 National Electrical Code (NEC), NFPA 70®, Section 250.4(A)(2) as: Normally non-current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected to the earth so as to limit the voltage to ground on these materials. So, the thought is, just stick a wire in the earth and call it good, right? Well not exactly, it goes much deeper; there must be an effective ground-fault current path created to ensure a safe electrical system. Basically, it is the creation of a low-impedance circuit that facilitates the operation of the overcurrent protective device (breaker or fuse). This path must be capable of safely carrying the maximum ground-fault current likely to be imposed on it from any point on the wiring system where a ground fault may occur to the electrical supply. The earth itself is not considered an effective ground-fault current path, so sticking the wire in the ground is not enough.

Proper Grounding

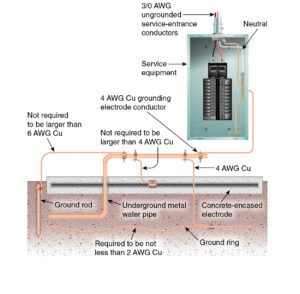

Proper grounding of electrical equipment starts at the foundation of a building or structure. According to 250.20(B) of the 2020 NEC alternating-current (AC) systems of 50 volts to 1000 volts must be grounded which means referenced to earth. This is accomplished through the grounding electrode system installed in accordance with the NEC. Having a strong grounding electrode system stabilizes voltage and helps to clear ground faults. The 2020 NEC, Section 250.50 gives the outline of a grounding electrode system and section 250.52 lists the approved grounding electrodes. A few of the more efficient grounding electrodes for buildings and structures are:

Proper grounding of electrical equipment starts at the foundation of a building or structure. According to 250.20(B) of the 2020 NEC alternating-current (AC) systems of 50 volts to 1000 volts must be grounded which means referenced to earth. This is accomplished through the grounding electrode system installed in accordance with the NEC. Having a strong grounding electrode system stabilizes voltage and helps to clear ground faults. The 2020 NEC, Section 250.50 gives the outline of a grounding electrode system and section 250.52 lists the approved grounding electrodes. A few of the more efficient grounding electrodes for buildings and structures are:

- Metal Underground Water Pipe

- Metal In-ground Support Structures

- Concrete-Encased Electrode, also known as: footer or Ufer ground.

- Ground Ring

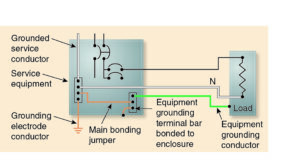

A grounding electrode system is the connection to earth, through the code required grounding electrodes. The grounding electrodes then get connected back to the buildings electrical service via a grounding electrode conductor (GEC). The GEC is terminated on the neutral bar in the building or structure’s electrical service equipment alongside the grounded (neutral) conductor. The neutral bar is bonded (connected) to the service equipment enclosure through a main bonding jumper, which creates an effective ground-fault current path for the electrical system.

An effective ground-fault current path has been established to the earth, now what? How is the electrical equipment going to be properly connected to the earth? Through the equipment grounding conductor (EGC). EGCs come in various sizes, types, and materials as found in the 2020 NEC, Section 250.118. Some of those are:

- Copper, aluminum, or copper-clad aluminum conductors

- Rigid metal conduit (RMC)

- Intermediate metal conduit (IMC)

- Electrical metallic tubing (EMT)

Frequently, EGCs are the raceway system, RMC, IMC, or EMT. These types of EGCs are bonded together and to the equipment enclosure through a series of listed set screw or compression couplings and connectors. Most connectors utilize lock nuts or bond bushings for the connection to the electrical equipment or enclosures. Where bond bushings are used, they require an additional conductor to connect to the electrical equipment grounding terminal, neutral bar, or EGC bar to complete the effective ground-fault current path. With this type of EGC, the electrical equipment grounding is more prone to human error or mechanical failure, therefore the effective ground-fault current path may not be as sound. While EGCs that are an electrical conductor such as copper, aluminum, or copper-clad aluminum conductors, these tend to be more effective due to the direct connection to the electrical equipment, enclosure, neutral bar, or EGC bar. There is less opportunity for failure with this type of EGC because of reduced number of connection points. In general, when installing an EGC, the approved EGC shall be contained within the same raceway, trench, cable, or cord from the electrical service or sub-panel as the feeder or branch circuit conductors that provide power to the electrical equipment. From an electrical safety standpoint and looking at NFPA 70E®, Section 120.5(8), where there is a possibility of induced voltages all circuit conductors and circuit parts should be grounded before touching them. This is one of the potential steps for establishing an electrically safe work condition (ESWC), so a weak or non-functioning EGC would make it difficult or impossible to create an ESWC when the need for replacing or maintaining the electrical equipment arises.

Study and dissect Article 250 of the 2020 NEC to discover more about grounding and creating an effective ground-fault current path. Properly grounding of electrical equipment sounds simple but is more important than is often realized. Failure to properly ground electrical equipment may prevent the overcurrent protective device from working properly and therefore not effectively clearing a ground-fault, which could result in a shock, electrocution, or arc flash incident. There is much more that goes into proper grounding of electrical equipment than most people think. Always double check the work, terminations, and the effectiveness of the equipment grounding conductor to ensure a safe equipment grounding system. ESW

Dean Austin is Senior Electrical Content Specialist at the National Fire Protection Association (NFPA). In his current role, he serves as an electrical subject matter expert in the development of products and services that support NFPA documents and stakeholders. NFPA 70 the National Electrical Code® (NEC®) and NFPA 70E are now available in NFPA LiNK™, the association’s information delivery platform with NFPA codes and standards, supplementary content, and visual aids for building, electrical, and life safety professionals and practitioners. Learn more at nfpa.org/LiNK.

Share on Socials!

Considerations When Evaluating FR/AR Apparel

Arc Flash Labels: What You Need to Know

Future Shock: As the World Goes Electric, Workers Must Be Protected

Leaders in Electrical Safety

• Aramark

• Bowtie Engineering

• Enespro

• Ericson

• I-Gard Corporation

• IRISS

• KERMEL, INC.

• Lakeland Industries

• MELTRIC Corporation

• National Safety Apparel

• National Technology Transfer

• Oberon

• Saf-T-Gard

• SEAM Group

Subscribe!

Sign up to receive our industry publications for FREE!